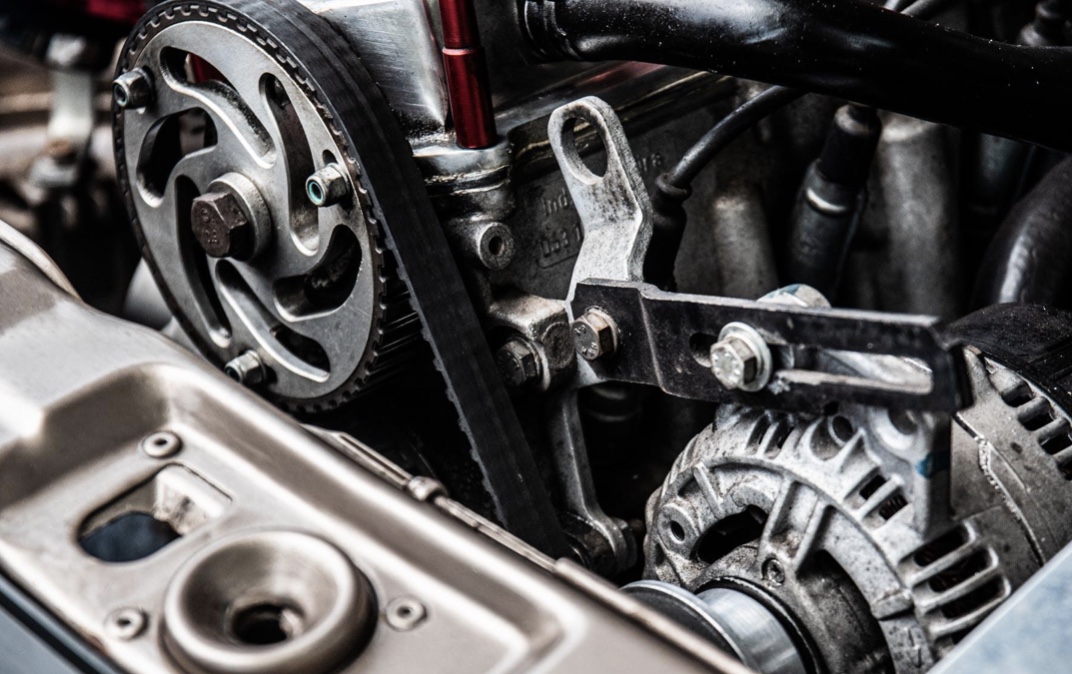

Machinery. At some point in the history of mankind, machines became an important part of our progress. Without them, an incredible number of processes would take considerably more time and effort than it takes nowadays, and thanks to it, we managed to advance as a race towards the path of development.

Many manufacturing processes rely on this aspect of progress. The cars we use to get to our jobs as well as the electric staircases and elevators that we conveniently use to move inside of a mall or shopping center… Many things present in today’s society are only possible thanks to them.

But why is machinery so important? Well, it is mainly because many machines used currently are used in metalworking. And, considering the great deal of metal components used in a lot of our tools and goods, it is not surprising to say that, thanks to metalworking, we are capable of enjoying several amenities.

That being said… What is metalworking? Are there different types of metalworking procedures? What are they used for? And what are considered conventional and nonconventional metalworking machines? You might have a lot of questions, but don’t worry, we do have a lot of answers as well!

The Core Concept of Metalworking

Metalworking can be simply described as the process in which metals are manipulated for the sole purpose of shaping it into a form that is efficient at dealing with a certain need. There are many examples we can provide, but some good examples in where metalworking is used for, include:

- Medical equipment and gear

- Automobile parts and other complex components required for cars, ships and even airplanes and spaceships

- Components used for the creation of doors and frames

- Tools required for several fields such as electronics and construction work

Back in the day, this practice was performed by people who were known as blacksmiths, which used tools such as anvils and hammers, as well as forges that created incredible levels of heat, to create tools and components.

Nowadays, most metalworking processes are managed through the help of equipment known as machinery. Although there are many different types of metalworking techniques, most of them rely on two particular types of machines: Conventional and Nonconventional.

Conventional Machinery

Conventional machines are the ones that usually involve direct contact with the metals that need reshaping. A good example of this is how a hydraulic hammer would strike a sheet of metal several times under the desired shape, or how a fast-rotating cutting machine reduces the volume of a sheet of metal until the desired design is obtained.

Now, a couple of decades back, this was the most common type of metalworking there was, since it was simple and easy to understand, and also, it was the only one science and technology were able to provide.

And although it is still largely used all around the world, as mankind progresses in many different fields, more complex designs are required, thus nonconventional machines started to become more and more popular among machine shops, and there’s a reason for that!

Nonconventional Machinery

The concept of nonconventional machinery is very simple: They are metalworking machines that are capable of shaping metals without actually coming into contact with them. At first, this might sound a little bit complicated, but in fact, it is a very simple process.

Let’s say that nonconventional machines rely on other things other than brute physical power and specific features to shape metals, yet it pretty much uses the same concept. A very good example of this would be a hydro cutter and hydroforming machine.

As the name implies, a hydroforming machine relies more on the power of high-pressure water to shape metals. A raw piece of metal that needs shaping is placed inside of the machine along with a die and a hammer. Then, the device shoots high-pressured water to push the hammer, which then pushes the metal onto the die, shaping it in the process. Now, a hydro cutting machine follows the same concept. It uses high-pressure water to cut thin (and sometimes thick) sheets of metal.

Noticed it? On paper, the machines actually never get into contact with the metal that is being shaped! On the contrary, it relies on other components such as liquids to do the job instead.

Other good examples of nonconventional machines found in the industry today, include:

- Plasma cutting machines

- Tools that use electric arcs

- Laser beams

- Electric beams

- Infrared beams

Why Nonconventional Machinery is Becoming Popular

There are many reasons why nonconventional machinery is becoming very popular in the industry of metalworking, but the most important reason is their capability to create high-quality pieces of work that are a lot more intricate, thus, almost impossible to create through traditional conventional machinery processes.

This has allowed several industries to bloom and achieve many things that once upon a time were considered unachievable, allowing the metalworking industry to aid mankind in its path towards progress. And thankfully, we have multiple examples of companies that are capable of providing such services, such as the UHI Group, which is capable of providing a wide range of services for many different purposes, procedures and industries.

Another thing to add is the fact that a lot of nonconventional machines are capable of doing this without requiring as much maintenance and resources, thus greatly reducing costs and the need for manpower, which can then be relocated in other aspects related to metalworking for the sake of improving both performance and productivity.

Of course, it is always important to understand that, although nonconventional machines have their advantages, there’s still some field of work for conventional procedures.

Machine shops that rely on both types of metalworking processes are usually the ones more suitable to handle a wider range of customers and orders, since they have the capacity of deciding how to handle their needs in a way that suits their requirements the most, without losing time, efficiency, and quality in the process.